11.2 GENERAL DESIGN CONSIDERATIONS

Prior to the actual design of a space engine system, it is necessary to examine the basic engine parameters to determine their influence on the spacecraft's ability to perform its intended mission. Here, again, an overriding consideration is reliability. Typical space missions include the establishment of an orbit around a planet following a transfer from Earth which may last several months or years. The ability of a propulsion system to coast in space for these prolonged periods and then fire reliably is typical for many contemplated missions. It is one of the foremost considerations in the design of space engines. Based on mission, trajectory. and payload requirements, the following major design areas must be examined for the optimization of one or a group of propulsion systems: (1) Propellant type (2) Vehicle system operational requirements (3) Mission environmental effects

Several different designs (assuming various propellants, feed systems, chamber cooling methods, etc.) may be conducted simultaneously for a given space mission. These designs must be carried far enough to evaluate their relative merits such as reliability and performance, and to establish the advantage of one design over the other. An optimum system design should thus emerge.

Selection of Propellants

Various aspects of liquid rocket propellants have been discussed in section 1.4. Here we will discuss the characteristics which are pertinent to their selection for space engine application. The reliability and performance of a spacecraft will depend greatly on the propellants used. This is of paramount importance in establishing the optimum design criteria and final operational capabilities of a vehicle. For any planned space mission, the projected program time periods, as related to the anticipated state of the art and operational reliability of the propellants to be used, should be the first criterion for their selection. Propellants with undesirable characteristics and those that have no advantages over similar, more desirable types should be eliminated early in the studies. In addition, propellants are selected on the basis of the following:

- Specific impulse.-The criterion of specific impulse is, perhaps, the most commonly used basis for comparison in nearly all propellant evaluations. For a given initial spacecraft mass (limited by the payload capability of the launch vehicle) and required mission velocity increment, the mission payload capability is a function of the main engine system specific impulse and the spacecraft inert weight, as indicated by equation (2-1). Similarly, for a given spacecraft initial mass, inert weight, and payload, the mission velocity increment capability is directly proportional to the main engine system specific impulse. The specific impulse of a reaction control engine system affects directly its system package weight. A higher specific impulse will result in a lower system weight for a given total impulse requirement.

- Operating temperature.-In an overall vehicle optimization study, the criterion of specific impulse must not be used as the only hard-and-fast rule for propellant selection, because the problem of maintaining the propellants at temperatures that permit effective use of the propulsion system after coast is an additional, major consideration in spacecraft design. The requirement for thermal control of the propellants during coast affects the selection of the propellants and the vehicle configuration. Heat transfer between propellants, and between propellants and other vehicle components, must be considered, as well as heat radiation out to space, in from the Sun, and between vehicle components. Studies have indicated the feasibility of insulating the propellants against excessive temperature changes, even during long coast periods in deep space missions. However, for the cryogenic propellants more insulation weight is required than for Earth-storable propellants. This difference becomes greater the longer the mission coast periods.

- Density.-The bulk density of a propellant combination has a pronounced effect on vehicle payload. This can most easily be seen in the case of the combination, the specific impulse of which is comparatively low, as compared to or . However, its bulk density advantage may result in a higher ideal velocity increment for certain space missions.

- Ignition characteristics.-Hypergolicity of the propellant combination used in space missions is always considered very desirable to effect a simpler and more reliable engine system, particularly for multiple starts.

- Cooling and other characteristics.-Some propellants are excellent coolants (for regenerative or film cooling), while others have little cooling capability. The propellant combination will determine the combustion temperature and the gas constituents, which vary widely as to their compatibility with chamber materials, especially with ablative or refractory materials which are frequently used in space engines.

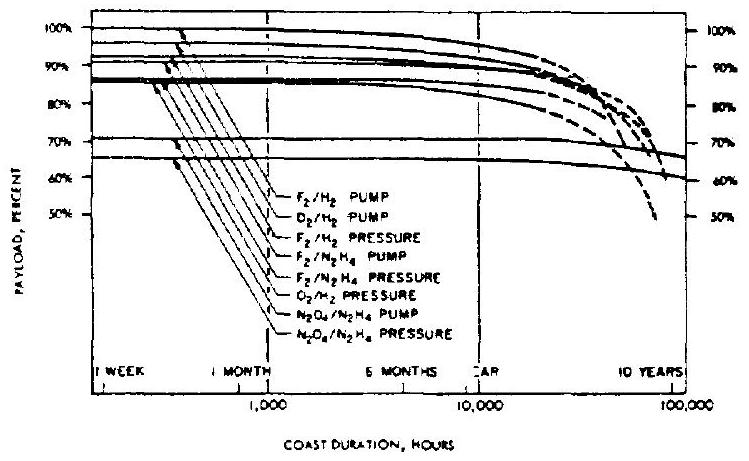

If possible, all propulsion systems in a spacecraft should use the same propellant combination. However, in some applications the reaction control engines are also used for propellant settling in the main system tanks. Thus they must be supplied by separate tanks equipped with positive expulsion devices. Different propellants may have to be used in this case. Characteristics of various propellants suitable for space engine applications are summarized in table 11-1. Characteristic trends of relative payload capabilities versus mission coast duration, for various propellants and engine systems, are shown in figure 11-2. It can be seen that for coast periods up to about 4300 hours ( 6 months). there is no significant change in payload capability.

Figure 11-2.-Effect of mission coast duration on relative payload capabilities of various propellant engine systems for a given mission velocity increment.

Figure 11-2.-Effect of mission coast duration on relative payload capabilities of various propellant engine systems for a given mission velocity increment.

Vehicle System Operational Requirements

After the vehicle system operational requirements have been analytically established for a given space mission, many design parameters and special considerations for the engine system or systems can be derived. Principal areas of consideration, in addition to propellant selection, are:

Table 11-1.-Comparison of Various Liquid Propellant Combinations for Space Engine Applications

| Propellant combination | Specific impulse, seconds | Density impulse. sec-gm/cc | Freezing and boiling points . oxidizer/fuel (FP)(BP)/(FP)(BP) | Mixture ratio, O/F | Combustion temperature, | Remarks |

|---|---|---|---|---|---|---|

| 474 | 241 | 9.3 | 6440 | Hypergolic | ||

| 456 | 143 | 4.7 | 5110 | Nonhypergolic | ||

| 430 | 424 | 3.5 | 7010 | Hypergolic | ||

| 420 | 357 | 2.15 | 5910 | Hypergolic | ||

| 419 | 551 | 2.4 | 7285 | Hypergolic | ||

| 417 | 451 | 5.6 | 6700 | Nonhypergolic | ||

| 408 | 303 | 2.0 | 5960 | Nonhypergolic | ||

| 402 | 254 | (35)(236)/(-265)(-135) | 1.2 | 4085 | Nonhypergolic | |

| 375 | 340 | 2.9 | 5710 | Nonhypergolic | ||

| 341 | 409 | 1.23 | 5513 | Hypergolic | ||

| MON/EMHF | 341 | 407 | (-23)(29)/(-76)(144) | 2.2 | 5330 | Hypergolic |

| MON/MMH. | 338 | 401 | 2.4 | 5370 | Hypergolic | |

| 339 | 408 | 2.1 | 5175 | Hypergolic | ||

| 339 | 407 | (11)(70)/(-63)(189) | 2.3 | 5290 | Hypergolic |

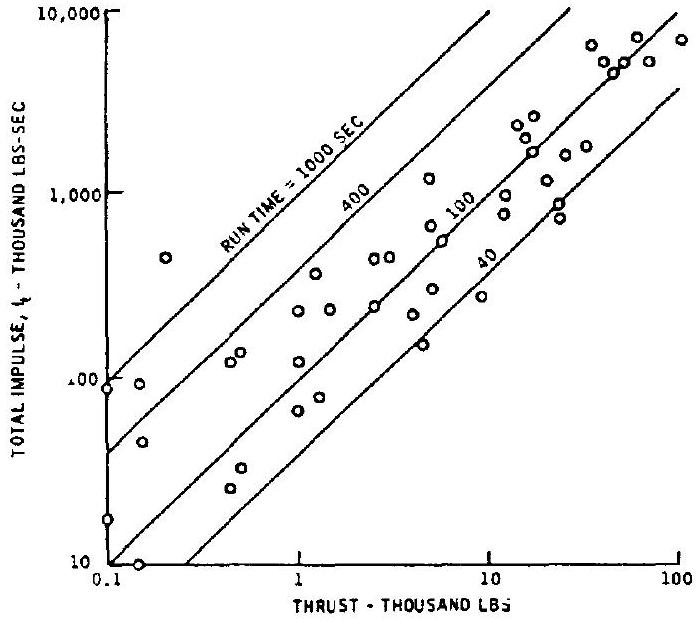

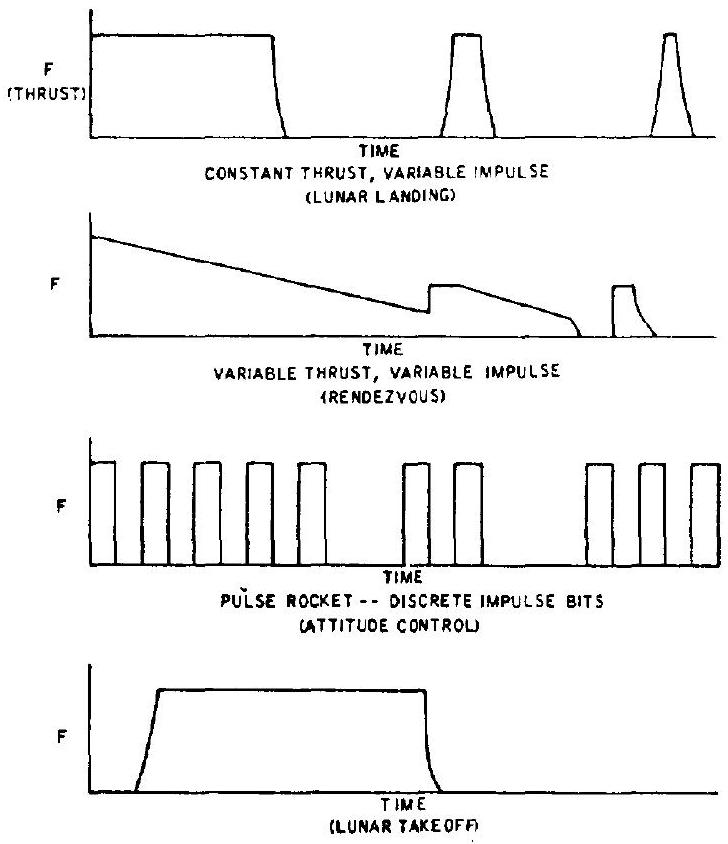

[^13]1. Engine system total impulse, design thrust level and run time.-These are determined and optimized by analyses of the mission trajectory, considering spacecraft operating limitations such as acceleration loads. Typical liquid propellant rocket engine total impulse, thrust, and run times for various space missions are presented in figure 11-3. Required mission total impulse and engine thrust level influence, to a large extent, the choice between a pressure feed and a pump feed system. 2. Engine system operating characteristics.This includes engine thrust throttling range, thrust as a function of time, number of starts and repetition rate, cutoff impulse and accuracy, and thrust vector control requirements. Most of these characteristics are determined by various projected spacecraft maneuvers. It may also be desirable for the same engine system to fulfill more than one type of maneuver, or to be reused on subsequent missions. Typical thrust-time histories for various spacecraft maneuvers are presented in figure 11-4. 3. Engine system design.-Experience has shown that multiple-start operation as required by most space engine systems has a more severe effect on a rocket engine than has continuous steady-state operation of comparable firing dura-

Figure 11-3.-Typical liquid propellant rocket engine total impulse, thrust, and run time for various space missions. (Coulbert, C. D., "Selecting Cooling Techniques for Liquid Rockets for Space Craft," J. Spacecraft and Rockets 1, 129-139, 1964.)

Figure 11-3.-Typical liquid propellant rocket engine total impulse, thrust, and run time for various space missions. (Coulbert, C. D., "Selecting Cooling Techniques for Liquid Rockets for Space Craft," J. Spacecraft and Rockets 1, 129-139, 1964.)

tion. This may be expected, considering that continuous operation involves a minimum of control components and actuations. Multiple starts, on the other hand, require that each component responds perfectly each time it is called upon. In addition, multiple starts require much longer periods of absolutely minimum propellant and pressurant leakage. Therefore, more rigorous approaches toward improved reliability, such as component or subsystem redundancies, must be considered in the design. 4. Engine system component design.-Besides mission environmental effects (to be discussed below), the detail design of the engine system components are directly affected by the spacecraft design configurations. For instance, the location of the system (internal in or external to the spacecraft) determines the feasibility of radiation cooling for the thrust chamber. Engine space envelope limitations affect the choice of nozzle type, allowable expansion area ratio, or even the feed system type. (In some applications a pump feed system affords a much higher

Figure 11-4.-Typical liquid propellant rocket engine thrust-time histories for various spacecraft maneuvers. (Coulbert, C. D., "Selecting Cooling Techniques for Liquid Rockets for Space Craft," J. Spacecraft and Rockets 1, 129-139, 1964.)

Figure 11-4.-Typical liquid propellant rocket engine thrust-time histories for various spacecraft maneuvers. (Coulbert, C. D., "Selecting Cooling Techniques for Liquid Rockets for Space Craft," J. Spacecraft and Rockets 1, 129-139, 1964.)

expansion area ratio for a given envelope.) The structural design of the system components is influenced by the maximum vehicle acceleration and by vibration loads.

Mission Environmental Effects

After the propellants have been selected and the basic propulsion system design established, with preliminary considerations of mission environmental effects, it is possible to examine the various engine subsystems in cletail to determine which components or phase of system operation is still affected by the projected mission environment in space. The characteristics of this environment include the following:

- High vacuum.-The low ambient pressures experienced in space missions may cause vaporization of metals and partial or complete removal of film or adsorbed gas layers at the surface of the material. Principal problems associated with high-vacuum conditions are: (a) Reduced ability of a component to perform its function, due to mass loss through material vaporization or bulk property changes. (b) Changes in the radiative heat transfer properties of the material, which could increase, to a destructive level, the bulk temperature of a component such as a radiation-cooled nozzle skirt. (c) Possibility of condensation of metallic vapor on electrical components, resulting in short circuiting. (d) Changes in the fatigue, frictional, and creep properties of materials, as well as the possibility of self-welding of metals. Design remedies against high-vacuum effects include material selection and proper location of the components within the vehicle to take advantage of nonvacuum environments.

- Thermal environment.-The thermal environment encountered in space missions, such as in Earth orbit or during the transfer phase in interplanetary flights, is an important consideration in the design of space propulsion systems, especially for the storage of the propellants. Three external sources of radiant energy must be considered when evaluating the thermal environment of a spacecraft. These are direct solar, albedo (solar energy reflected from a planet), and planetary emitted radiation. Direct solar radiation is the largest external heat source. It is therefore advantageous to orient the spacecraft for maximum protection from direct solar radiation to the vulnerable subsystems such as propellant tanks. The quantitative evaluation of thermal radiation in space indicates that damage to some components may result from the excessive absorption of radiant energy, unless protective means are applied such as reflective surfaces or coatings. A very real problem with the prediction of the thermal properties of materials in the vacuum is the lack of knowledge about the effect of the ever-present oxide-metal surface film on heat transfer mechanisms.

- Nuclear radiation.-The two most important effects of nuclear radiation in space on metals are the production of internal heat, and dislocation of the atoms within their crystalline structure. The nuclear particles of interest are fast neutrons, lower energy protons, alpha particles, electrons, and gamma rays. The fast neutrons present the most severe problem. It is known, however, that they do not exist to a great extent in space. Generally, the total radiative flux from all nuclear radiations is not sufficient to cause any appreciable damage to metals over a period less than 2 years.

- Meteoric bombardment.-Spacecraft will be exposed to the impact of meteoroids ranging in size from microscopic dust particles to bodies of asteroid dimensions with a wide distribution of kinetic energies. Collision of the spacecraft with these materials would result in surface erosion, punctures, or total destruction of the vehicle. The ideal protection for propulsion system components would be to locate them entirely within the vehicle. This, however, is usually not practical for parts such as the thrust chamber nozzle skirt. Therefore, adequate consideration must be given to the design of these parts with respect to the cited effects.

- Effects of gravity.-The absence of acceleration forces, as well as the presence of large acceleration forces, should cause no mechanical design problems if proper provisions are made in the design phase. The main problem will be with the propellant feed system. This can be overcome by positive expulsion or by providing propellant settling rockets (which themselves would require a positive expulsion feed system).